Today we’re talking about Lean. No, not the fat content of ground beef. Not the orientation of the famous Tower of Pisa. The “Lean” in question is a business principle originating from the manufacturing industry (more specifically the Toyota Production System). Lean principles emphasize creating more value for customers with fewer resources.

In essence, Lean involves continuously improving processes by identifying and eliminating activities that don’t add value—referred to as “waste.” This could be anything from excess inventory and unnecessary steps in a process to long wait times and inefficient use of materials.

The goal of Lean is to streamline operations, improve quality, reduce costs, and increase customer satisfaction. It’s about working smarter, not harder, by focusing on efficiency and effectiveness across all areas of a business. Sounds good, right? Let’s see how it applies to the construction industry, and why you should start implementing these practices.

What is Lean Construction?

At its core, Lean Construction is about maximizing value while minimizing waste, all while fostering a culture of continuous improvement. Unlike traditional construction methods that often operate in silos, Lean Construction encourages collaboration, transparency, and problem-solving across all stages of a project.

Lean Construction vs. Traditional Construction

Comparing Lean Construction to traditional construction methods reveals stark differences. Traditional construction often involves fragmented processes and inefficiencies, while Lean Construction emphasizes integrated project delivery, waste minimization, and resource optimization to improve productivity and quality.

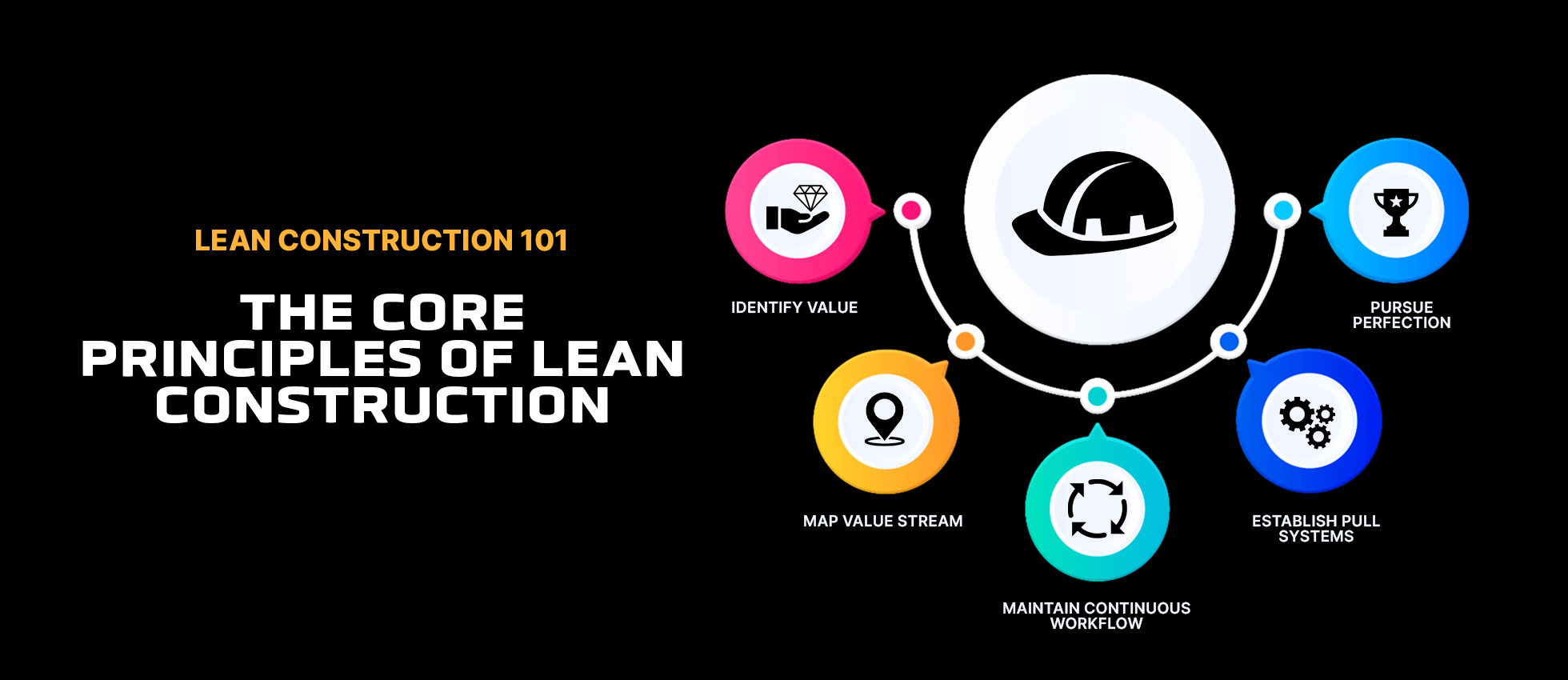

The 5 Core Principles of Lean Construction

Lean Construction is built on a foundation of key principles that, when implemented effectively, can lead to more successful projects and satisfied clients. Here’s a closer look at these guiding principles:

1. Identify Value from the Client’s Perspective

The foundation of Lean Construction is understanding what the client truly values. This principle emphasizes the need to clearly define the project’s goals from the outset and align every aspect of the construction process to deliver on those expectations. It involves actively engaging with the client to identify their priorities, whether it’s cost, quality, speed, sustainability, or a combination of these factors.

Example: On a commercial office building project, the client might prioritize sustainability and energy efficiency. In this case, the construction team would focus on sourcing environmentally friendly materials, integrating energy-efficient systems, and ensuring that the building meets specific green certifications. By aligning the project with the client’s values, the team delivers a product that meets or exceeds expectations.

2. Map the Value Stream

Once you know what the client values, the next step is to map out every step of the construction process. This includes everything from design to delivery, identifying areas where waste occurs. Mapping the value stream allows you to visualize the entire process, uncover inefficiencies, and eliminate activities that don’t add value. The goal is to streamline the process, making it as efficient and cost-effective as possible.

Example: In a residential construction project, value stream mapping might reveal that materials are being delivered too early, resulting in storage issues and potential damage. By adjusting the timing of deliveries and ensuring that materials arrive just when needed, the project can reduce waste, minimize costs, and improve workflow efficiency.

3. Create Continuous Workflow

Interruptions in workflow are costly and can lead to delays and increased expenses. Lean Construction aims to create a seamless flow of work, minimizing these interruptions. This often involves breaking down the project into smaller, manageable tasks that can be completed in a more efficient and timely manner. The goal is to maintain a steady and continuous flow of work, reducing bottlenecks and keeping the project on track.

Example: On a large infrastructure project, such as a bridge, the construction team might break the work into phases—foundation, superstructure, and finishing. By carefully scheduling each phase and ensuring that materials and labour are available when needed, the project maintains a continuous workflow, avoiding costly delays and ensuring that each phase is completed on time.

4. Establish Pull Systems

Instead of pushing tasks through the construction process based on a set schedule, Lean Construction advocates for a pull system. In a pull system, work is only started when there is a demand for it, ensuring that resources are used efficiently. This approach helps to prevent overproduction, reduce excess inventory, and ensure that each task is completed just in time for the next phase of the project.

Example: On a large commercial construction project, such as a multi-story office building, a pull system might be applied to the delivery and installation of glass windows. Instead of having all the windows delivered at once, which could lead to storage issues and potential damage, the windows are delivered and installed floor by floor as the structure progresses. This way, the installation crew pulls the windows only when a specific floor is ready, ensuring that the windows are installed promptly without causing delays or requiring additional storage space. This approach minimizes waste and enhances efficiency by aligning the supply of materials directly with the pace of construction.

5. Pursue Perfection

Lean Construction is all about continuous improvement. The pursuit of perfection means constantly seeking ways to enhance efficiency, quality, and client satisfaction. Even after a project is complete, there should be a focus on reflecting, learning, and refining processes for future projects. This principle encourages a mindset of always looking for ways to do things better, leading to incremental improvements over time.

Example: After completing a project, a company should conduct a thorough review to identify areas where communication could have been improved. This review could expose delays in communication leading to the decision to implement a new project management tool for future projects. By continuously refining their processes, the team is better prepared for the next project, ultimately delivering better results and higher client satisfaction.

The Benefits of Lean Construction

Adopting Lean Construction principles can lead to numerous benefits, not just for the contractors and workers, but for clients as well. Here’s why more and more companies are embracing this methodology:

Reduced Waste: By eliminating non-value-added activities, Lean Construction significantly cuts down on waste—whether that’s materials, time, or labour. This leads to cost savings and a more sustainable approach to building.

Improved Collaboration: Lean Construction fosters a culture of teamwork and open communication. By bringing all stakeholders together early in the process, potential issues can be identified and addressed before they become major problems.

Faster Project Completion: With a focus on continuous workflow and efficiency, projects are often completed faster, without sacrificing quality. This means clients can enjoy the benefits of their new buildings sooner rather than later – and you can move on to your next project. A Dodge research study showed that 45% of projects using Lean methodology were completed ahead of schedule.

Enhanced Quality: The pursuit of perfection inherent in Lean Construction leads to higher quality outcomes. With every step of the process focused on delivering value, the end result is a building that meets or exceeds client expectations. A report from McGraw Hill Construction states that 84% of contractors using Lean practices reported higher quality construction and 80% reported greater customer satisfaction.

Reduced Cost and Improved Profitability: Lean Construction’s emphasis on efficiency and the elimination of waste leads to substantial cost savings, directly impacting the bottom line. By streamlining processes and focusing on value-added activities, projects are less likely to experience costly delays or overruns. In fact, the same Dodge research study found that 70% of projects using high intensity Lean practices were completed under budget, highlighting the strong correlation between Lean practices and enhanced profitability.

Implementation Challenges and Barriers

Implementing Lean Construction is not without its challenges. One of the biggest hurdles is resistance to change, as teams and management may be hesitant to move away from traditional methods that they are accustomed to. Additionally, proper training and education are essential to ensure everyone involved understands and effectively applies lean principles, which can require a significant time and resource investment upfront.

The initial costs of adopting Lean practices, including the necessary tools and software, can also be a barrier, even though these costs are often offset by long-term savings.

Finally, shifting the organizational culture to embrace the collaboration, transparency, and continuous improvement central to lean construction can be a complex and gradual process.

How to Start Implementing Lean Construction in Your Projects

Implementing Lean Construction starts with a commitment to change and a willingness to adopt new methodologies. You can start with these four steps:

- Educate your team on the core principles of Lean Construction

- Identifying areas where waste can be reduced

- Streamline processes and improve efficiency with tools like the Last Planner System, Value Stream Mapping, and Just-In-Time delivery

- Embrace technology, such as construction management software and digital forms

Remember, it’s important to start small, with pilot projects or specific aspects of larger projects, to build momentum and demonstrate the benefits before rolling out Lean practices on a broader scale.

Lean Construction Statistics

- 37% of contractors are not familiar with Lean Construction practices. (McGraw Hill Construction)

- 55% of contractors believe the construction industry is inefficient. (McGraw Hill Construction)

- High Lean intensity projects are three times more likely to complete ahead of schedule. (Lean Construction Institute)

- High Lean intensity projects are two times more likely to complete under budget. (Lean Construction Institute)

- 23% of firms are taking steps to improve jobsite performance with Lean Construction techniques. (AGC)

How Corfix Supports Lean Construction

At Corfix, we’re committed to helping our clients implement Lean Construction principles in their projects. Our platform is designed to streamline communication, manage tasks efficiently, eliminate the reliance on paper forms, and ensure that everyone is on the same page—keeping projects on time and within budget.

By using Corfix, you can easily map out your value stream, establish continuous workflows, and create a culture of continuous improvement. We believe that by embracing Lean Construction, you can not only improve your bottom line but also deliver projects that truly stand the test of time.

Ready to take your projects to the next level? Let’s build smarter, together. Get a demo.