Cranes are among the most essential and powerful pieces of equipment on construction sites. But between their size, complexity, and role in lifting heavy loads, they pose significant safety risks if not properly maintained. Regular crane inspections are key to ensuring their safe operation, helping prevent accidents and breakdowns.

This guide will walk you through the critical aspects of construction crane inspections, how often they need to occur, who should perform them, the applicable regulations, and the main components that need to be inspected.

Why Are Crane Inspections Necessary?

OSHA Regulations for Crane Inspections (Pre-shift, Monthly, Annual)

Who Should Inspect a Crane?

How to Conduct a Crane Inspection in 4 Steps

Crane Inspection Certification

Mobile Crane Inspections

But first …

Why Are Crane Inspections Necessary?

From 2011 to 2017, an average of 42 crane-related deaths occurred each year in the U.S., according to the Bureau of Labor Statistics (BLS). Many of these incidents could be avoided with regular inspections and proper training. Additionally, approximately 490 non-fatal crane incidents occurred in 2020, many of which resulted in worker injuries severe enough to increase absenteeism.

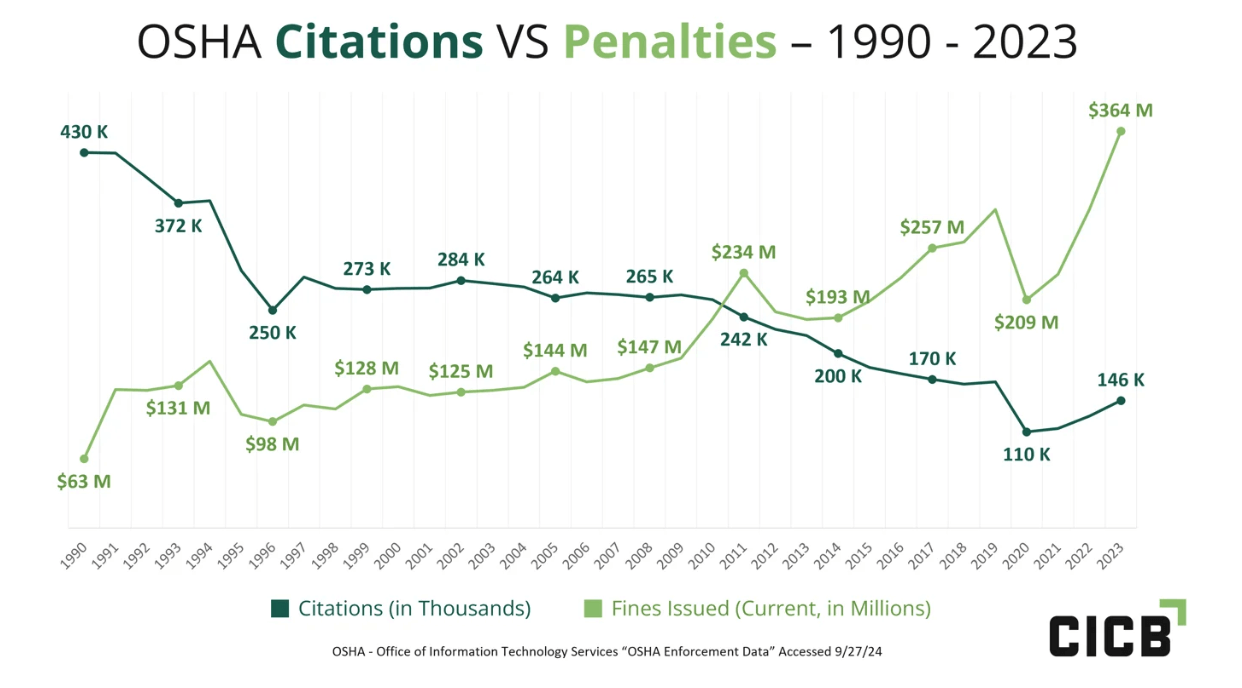

Fines for crane-related safety violations can be steep. Across the board, OSHA has massively increased enforcement of regulations, leading to a substantial increase in fines. While citations are dropping (from 430,000 in 1990 to 146,000 in 2023) fines have gone up almost 600%, — from $63M to $364M in the same time span.

The bottom line? Violations are being taken very seriously, and they can be very costly.

Inspections are the Top Crane-Related OSHA Violation

In the category of crane-related violations, “Inspections” top the list. And they don’t just top the list – they account for more citations than the next two highest in volume combined.

By investing in regular inspections that comply with regulations, construction companies can avoid hefty fines, reduce downtime, and most importantly, protect their workers from serious harm.

Here is a list of the top 10 crane violations and the associated standards:

1. Inspections 1926.1412

2. Signal person qualifications 1926.1428

3. Power line safety 1926.1408

4. Keeping clear of the load 1926.1425

5. Operation 1926.1417

6. Assembly/Disassembly 1926.1404

7. Operator Qualification & Certification 1926.1427

8. Hoisting personnel 1926.1431

9. Wire rope-inspection 1926.1413

10. Training 1926.1430

OSHA Regulations for Crane Inspections

The applicable OSHA regulations covering construction cranes and their inspections are as follows:

- 29 CFR 1926: Safety and Health Regulations for Construction

- 1926 Subpart CC: Cranes and Derricks in Construction

- 1926.1412 Inspections

- 1926.1413 Wire rope—inspection

- 1926.1435(f) Tower cranes: Inspections

- 1926 Subpart CC: Cranes and Derricks in Construction

These standards for crane inspections apply to power-operated equipment (in construction) that can hoist, lower, and move suspended load. This includes, but isn’t limited to:

- Articulating cranes

- Crawler cranes

- Floating cranes

- Tower cranes (such as a fixed jib, luffing boom, and self-erecting)

- Locomotive cranes

- Mobile cranes (such as wheel-mounted, rough-terrain, all-terrain, commercial truck-mounted, and boom truck cranes)

- Dedicated pile drivers

- Service/mechanic trucks with a hoisting device

- Pedestal cranes

- Portal cranes

- Overhead and gantry cranes

- Straddle cranes

- Sideboom cranes

- Derricks

Common Misconceptions Around the Standards for Crane Inspections

OSHA 1926 and OSHA 1910 are two sets of safety standards under the Occupational Safety and Health Administration (OSHA) that apply to different work environments. The differences between OSHA 1926 and OSHA 1910 in relation to cranes lie mainly in the contexts and specific applications within the construction and general industry sectors, as well as in inspection frequency and focus.

The regulation applicable to construction cranes (including tower cranes and mobile cranes)— 1926.1412 — requires visual inspections for each shift, detailed monthly inspections with documentation, and a comprehensive annual inspection requiring disassembly.

The OSHA standard 1910.179, which mentions “periodic inspections” and “frequent inspections” for cranes, applies to overhead and gantry cranes, which have similar travel characteristics— it does not apply to cranes used in construction settings.

Periodic and frequent inspections apply to cranes used in non-construction environments, such as general manufacturing, warehousing, and industrial settings. Frequent inspections can be performed on daily to monthly intervals, while periodic inspections are to occur on 1 to 12 month intervals.

>> OSHA Standards for Construction vs. General Industry <<

OSHA Crane Inspection Requirements

OSHA’s crane inspection requirements for cranes being used in a construction setting are outlined in 1926.1412, with some specific requirements for tower cranes found in 1926.1435. The standard details the three main types of inspections that must occur regularly:

- Each shift

- Monthly

- Annual/comprehensive

Each Shift / Daily Inspections

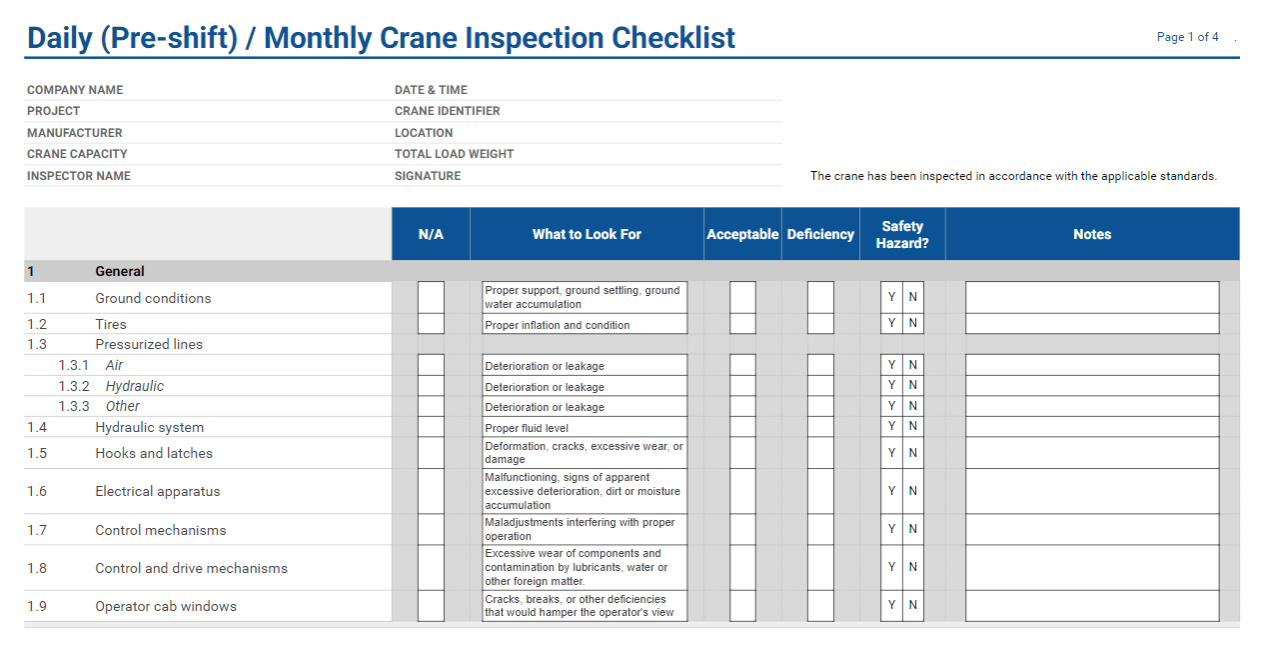

A visual inspection of the major crane components prior to each shift is required to determine if any deficiencies are present that would constitute a safety hazard, requiring correction or further investigation. Some components can only be assessed during operation, so the person inspecting must keep that in mind.

At a minimum, each shift inspection includes looking at:

- Control mechanisms

- Pressurized lines

- Hydraulic system

- Hooks and latches

- Wire rope and reeving

- Electrical apparatus

- Tires

- Ground conditions

- Cab windows

- Safety devices

No documentation is required for these inspections, but it is a best practice to use a daily crane inspection checklist to ensure that nothing is missed.

Monthly Inspections

Every month, the crane must be visually inspected in the same manner as before each shift. Documentation is required for monthly inspections and must include the items checked and their results as well as the name and signature of the person who conducted the inspection. The document must be retained for a minimum of three months from the date of the inspection.

For tower cranes, there are two additional inspections that must occur:

- Tower (mast) bolts and other structural bolts from the base up (or those above the upper-most brace support)

- The upper-most tie-in, braces, floor supports and floor wedges where the tower crane is supported by the structure

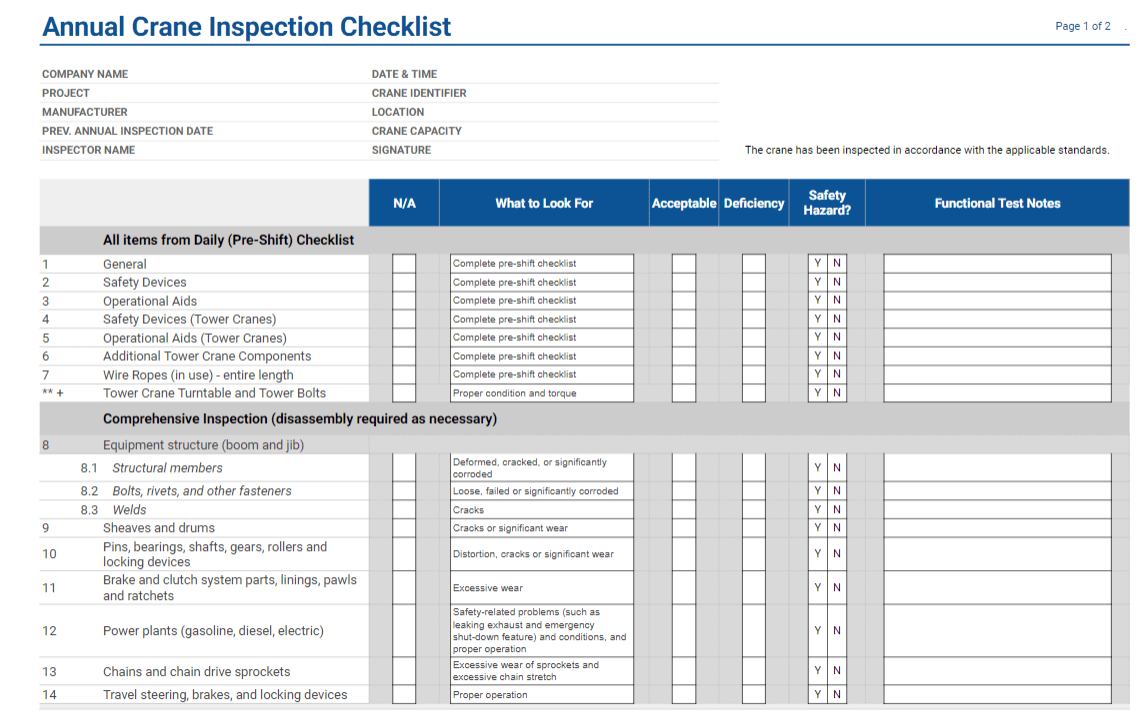

Annual Inspections

At least every 12 months, a comprehensive inspection must be conducted to determine the status of all the crane components from the “each shift” inspection as well as other major components and systems. The inspection will look for cracks, deformation, inaccuracies, excessive wear, and leaks. In order to complete the inspection, disassembly may be required.

The inspection must include functional tests and any deficiencies that are not considered a hazard must be added to the monthly inspection list.

The additional components and systems that need to be inspected on an annual basis include:

- Boom and jib

- Sheaves and drums

- Pins, bearings, shafts, gears, rollers and locking devices

- Brake and clutch system

- Safety devices

- Power plants

- Chains

- Hoses, fittings, and tubing

- Pumps and motors

- Hydraulic and pneumatic valves and cylinders

- Outrigger or stabilizer pads/floats

- Electrical components and wiring

- Warning labels

- Operator seat

- Steps, ladders, handrails, and guards

- Wire rope (normally hidden during shift and monthly inspections, subject to reverse bends, passing over sheaves)

For annual tower crane inspections specifically, all turntable and tower bolts must be inspected for proper condition and torque.

A document including the list of items inspected and the results as well as the name and signature of the person who conducted the inspection must be completed and retained for a minimum of 12 months from the date of the inspection.

Additional Inspections

In addition to the three discussed above, there are also requirements for pre-erection, post-erection, and idle equipment. A pre-erection inspection must take into account the components that will be difficult to inspect during operation and make note of any deficiencies that will need regular monthly monitoring. Before a crane can be used, a load test must be conducted post-erection, in accordance with the manufacturer’s instructions. If a crane is idle for three months or more, the monthly inspection routine must be used before initial use.

Who Should Inspect a Crane?

Daily, pre-shift crane inspections should be conducted by a “competent person” with the capability of identifying existing and predictable hazards and the authority to take corrective measures if necessary. This is often an employee who has received the appropriate safety training and understands the crane components, including what to look for when inspecting them.

Annual crane inspections must be conducted by a “qualified person”. A person is deemed qualified if they have successfully demonstrated the ability to identify hazards and resolve problems related to crane operation. This could include individuals possessing recognized degrees or certifications or someone with extensive knowledge gained through training or experience.

Qualified individuals can include:

- Certified Crane Inspectors

- A Registered Professional Engineer familiar with cranes

- Qualified Third-Party Inspectors

While some companies rely on in-house inspectors for daily and routine checks, many prefer or are required to engage third-party inspectors for more comprehensive assessments, such as annual certifications. These independent inspectors are often required for high-risk jobs, especially those involving public or government contracts, ensuring neutrality and adherence to all safety regulations.

Crane Inspection and Certification Bureau (CICB)

The Crane Inspection & Certification Bureau (CICB) is a leader in providing third-party inspections, training, and certification services for crane operators and companies. Many construction companies rely on CICB for their unbiased, neutral inspections, which are critical for ensuring compliance with OSHA standards and for qualifying cranes for public or government contracts.

CICB services include:

- Crane safety programs

- Third-party inspections for neutral assessments

- Certification services for crane operators and equipment

By leveraging CICB’s expertise, companies can ensure that their cranes meet regulatory requirements and reduce the risk of accidents and equipment failure.

How to Conduct a Crane Inspection in 4 Steps

To conduct a proper crane inspection, the following steps should be followed:

- Review manufacturer’s instructions: Each crane has specific guidelines for inspection based on its design and use. The OSHA standard states that any procedures around safe operation that are more comprehensive than the regulations must be followed.

- Perform a visual check: Look for visible signs of wear, damage, or deformation in critical components, such as wire ropes, hooks, and structural elements. Cracks, corrosion, or other obvious issues could compromise the crane’s safety. Follow a checklist that indicates specific parts and what to look for on each one to help guide your inspection.

- Test operational functions: Test the crane’s operational systems, such as hoists, brakes, and limit switches, to ensure everything is functioning properly. Operational testing ensures that all safety devices are in working order and capable of preventing accidents.

- Document the findings: Any issues or irregularities should be recorded and addressed immediately if they pose a safety risk. Keeping regular documentation and following pre-shift forms can help ensure that nothing is being skipped and ongoing issues are being properly monitored.

Crane Inspection Certification

There are no requirements under OSHA that state that a crane needs to be “certified” for operation. There must be routine inspections conducted and documented per the standard (pre-shift, monthly, and annually) by qualified personnel or third party agencies. These records must be retained for 3-12 months at a minimum.

Mobile Crane Inspection

Mobile cranes fall under the same standard as tower cranes (1926:1412) and other equipment that lifts and moves suspended loads. The inspection requirements for mobile cranes are the same as in the previous section OSHA Crane Inspection Requirements, which states that the cranes must be inspected each shift, monthly, and annually by a competent person.