You likely know a lot more about the better known wonders of the modern engineering world like the Golden Gate Bridge, Hoover Dam, Chunnel, and Eiffel Tower, but did you know that Scotland is home to the world’s first and only rotating boat lift?

That’s right, the Falkirk Wheel was designed to get boats from the Union Canal to the Forth & Clyde canal, which is 35 meters (115 feet) lower. This unique rotating boat lift is nestled between the vibrant cities of Glasgow and Edinburgh and opened to the public in 2002 as part of the Queen’s Golden Jubilee celebrations.

Why Was the Falkirk Wheel Built?

The idea for the Falkirk Wheel was born as part of the ambitious Millennium Link project, an initiative aimed at restoring navigability between the Union Canal and the Forth & Clyde Canal, reconnecting Glasgow and Edinburgh by water for the first time in over 35 years.

Traditional lock systems were originally used, but they took a day to pass through and had fallen into disrepair and were dismantled. So the project’s engineers and architects sought a more innovative and efficient solution. This quest for ingenuity led to the creation of the world’s only rotating boat lift.

What is a Boat Lift?

A boat lift is a device used to move boats between bodies of water that are at different elevations. Unlike traditional lock systems, which rely on a series of steps or chambers to raise or lower water levels gradually, a boat lift moves boats directly between levels, often in a single, efficient operation, similar to a Ferris Wheel. Boat lifts can be particularly useful in areas where space is limited or where the difference in elevation between two water bodies is too great for a traditional lock system to handle effectively.

Boat lifts are typically used in canals and waterways where there is a significant height difference between sections of the waterway. They are especially useful in reducing transit time for boats, as they can lift or lower vessels much faster than navigating through multiple locks. Also, boat lifts are often designed to be more energy-efficient and can become iconic landmarks, as seen with the Falkirk Wheel.

How Does the Falkirk Wheel Work?

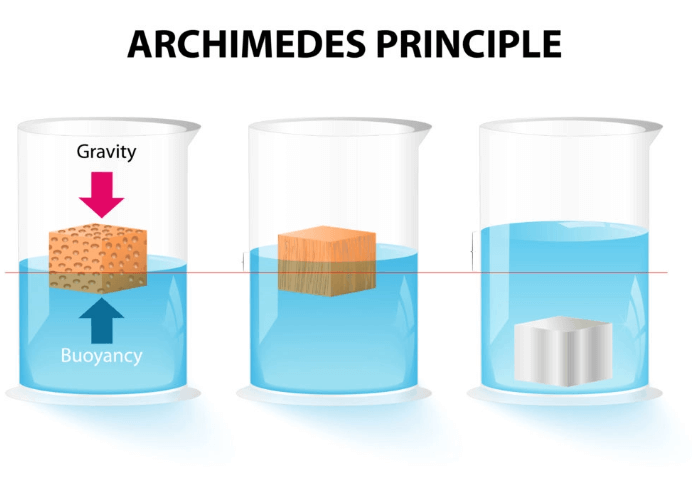

The Falkirk Wheel operates on a remarkably simple yet elegant principle of balance and Archimedes’ principle, which states that a floating object displaces its own weight in water. The two caissons are always in equilibrium, ensuring that the Falkirk Wheel remains stable and requires minimal energy to rotate.

The rotation process is powered by hydraulic motors, which provide the necessary torque to turn the Falkirk Wheel. The motors, driven by hydraulic pumps, are incredibly efficient, consuming only 1.5 kWh of energy per rotation. As the Falkirk Wheel turns, a complex gearing system ensures that the caissons remain level, allowing boats to be safely and smoothly lifted or lowered between the canals.

The entire rotation takes about five minutes, during which time the caissons rotate in opposite directions at half the speed of the Falkirk Wheel’s rotation, maintaining a perfectly balanced load. This careful balance is key to the Falkirk Wheel’s efficiency and longevity, ensuring that it continues to operate smoothly for years to come.

Building the Falkirk Wheel: A Step-by-Step Guide

The construction of the Falkirk Wheel was a monumental undertaking, requiring meticulous planning, innovative engineering, and precise execution. Here’s how this engineering marvel was brought to life:

Planning and Design

The design of the Falkirk Wheel is nothing short of extraordinary. The engineering firm Butterley Engineering, in collaboration with architects from RMJM, crafted a structure that would not only be functional but also aesthetically striking. The design was inspired by a Celtic double-headed ax and incorporates elements that evoke the elegance of an aquatic-themed mechanical sculpture.

As mentioned above, the idea for the Falkirk Wheel emerged as part of the Millennium Link project, aimed at reconnecting Scotland’s historic canals. The design process involved collaboration between engineers, architects, and various specialists to create a structure that was both functional and visually stunning. Inspired by a Celtic double-headed ax, the final design had to overcome several engineering challenges, including ensuring stability and integrating modern technology with aesthetic appeal.

Site Preparation and Groundwork

Falkirk was strategically chosen as the site for the Wheel due to its location between the two canals. Extensive geological surveys and environmental impact assessments were conducted before earthworks began. The foundations of the Falkirk Wheel were laid with reinforced concrete piles driven deep into the ground to support the structure’s immense weight.

Fabrication and Assembly

The components of the Falkirk Wheel, including its massive arms and central axle, were fabricated from over 1,200 tons of steel. These components were crafted at Butterley Engineering’s workshops before being transported to Falkirk.

The assembly process was a feat in itself, with the central axle, measuring 28 meters (92 feet) long and 3.5 meters (11.5 feet) in diameter, being one of the first major components to be installed. The two arms, each weighing 500 tons, were then attached with the utmost precision.

Integration and Testing

With the structural components in place, the intricate gearing and hydraulic systems were installed to ensure smooth operation. These systems were designed to keep the caissons level during rotation, a critical factor in the Falkirk Wheel’s functionality. Advanced control and safety systems were also integrated, automating its operation and ensuring safe, reliable performance.

Connection to the Canals and Final Testing

The final stages of the project involved connecting the Falkirk Wheel to the Union Canal at the top and the Forth & Clyde Canal at the bottom. This was accomplished through the construction of aqueducts and lock gates that manage water levels and boat traffic. Extensive testing was carried out, including both dry runs and tests with water and boats, to fine-tune the operation and ensure that everything functioned flawlessly.

Inauguration

The Falkirk Wheel was officially opened on May 24, 2002, by Queen Elizabeth II, marking the culmination of three years of planning, design, and construction. Since its inauguration, the Falkirk Wheel has become a major tourist attraction and a symbol of modern engineering excellence.

An Efficient Modern Marvel

One of the most impressive aspects of the Falkirk Wheel is its energy efficiency. Despite its massive size—standing 35 meters (115 feet) tall, with a diameter of 120 meters (394 feet)—the Falkirk Wheel uses just 1.5 kWh of energy per rotation, roughly the same amount required to boil eight kettles of water. This energy efficiency is achieved through a finely tuned balance, where the weight of the water-filled caissons (gondolas) carrying the boats remains equal, regardless of whether the caisson is full of boats or empty.

An Icon and Tourist Attraction

Since its opening, the Falkirk Wheel has become a must-visit destination for anyone interested in engineering, history, or simply the beauty of Scotland’s landscapes. It draws hundreds of thousands of visitors each year, offering boat trips that take passengers through, providing a unique perspective on this incredible structure.

The Falkirk Wheel isn’t just an engineering feat; it’s also an educational resource, offering insights into modern engineering, canal history, and environmental sustainability. About 500,000 visitors each year explore exhibits that detail the construction and operation of the Wheel, as well as enjoy the stunning views of the surrounding countryside.

Interesting Falkirk Wheel Facts

- Each gondola contains between 250,000L (66,000 US gal) of water.

- The combined weight of the two caissons is 500 tonnes.

- The gondolas can carry up to eight boats at a time.

- The Wheel contains more than 15,000 bolts, each one tightened by hand.

- It cost £17.5 million to build and the whole restoration project (Millennium Link ) cost £78 million.

- It was designed to last at least 120 years.